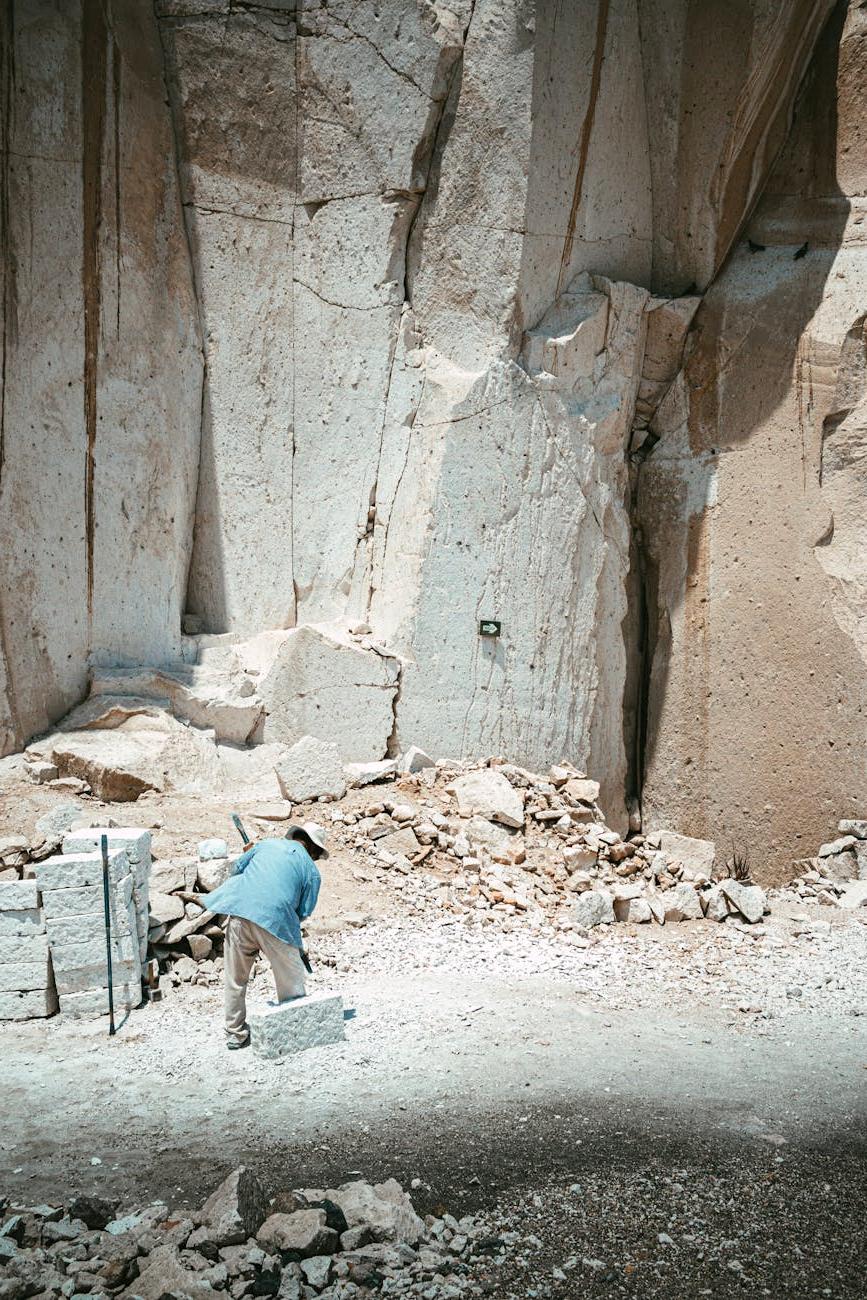

Revolutionizing Mining with Computer Vision

Advanced AI-powered ore sorting technology that increases efficiency by up to 40% while reducing environmental impact and operational costs.

Advanced AI-powered ore sorting technology that increases efficiency by up to 40% while reducing environmental impact and operational costs.

Our advanced ore sorting solutions leverage cutting-edge AI to transform mining operations

Process thousands of ore samples per second with millimeter-precision identification and classification.

Minimize tailings and waste by accurately identifying valuable minerals from gangue material.

Boost recovery rates by up to 35% with precise mineral identification and efficient sorting algorithms.

Our system combines multi-spectral imaging with deep learning algorithms to identify ore characteristics invisible to the human eye. Using hyperspectral cameras and 3D sensors, we can detect mineral composition, texture, and grade with unprecedented accuracy.

How our computer vision solutions deliver value across your entire operation

Increased Recovery

Cost Reduction

Global Installations

Operational Uptime

A seamless integration of advanced technology with your existing operations

Ore passes through our imaging system where multiple camera types capture detailed spectral signatures.

Our deep learning algorithms analyze the data in milliseconds to identify mineral composition and value.

The system makes real-time decisions on whether to accept or reject each piece of ore based on predetermined criteria.

High-speed air jets or mechanical devices separate the valuable ore from waste with precision timing.

Operations Director, GlacierPeak Mining

"The computer vision system has transformed our processing efficiency. We've seen a 32% increase in recovery rates and a significant reduction in operational costs."

Chief Engineer, CopperRidge Resources

"Implementation was seamless, and the results were immediate. The AI's ability to identify complex mineralogy has allowed us to process ore bodies we previously considered uneconomical."

Sustainability Director, AzureMinerals

"Beyond the economic benefits, the environmental impact has been substantial. We've reduced our tailings volume by 40% and significantly decreased our water consumption."

Join our newsletter to receive the latest updates on computer vision technology for ore sorting.

By subscribing, you agree to our Privacy Policy and Terms of Service.